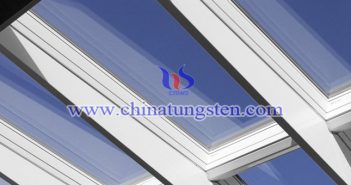

WO3 electrochromic film is a smart material that can be applied to architectural glass to obtain the so-called smart windows for thermal insulation and energy conservation. There are many methods for preparing such WO3 electrochromic film, such as, a spray method, a hydrothermal method, and an electrodeposition method. More details, please visit: http://www.tungsten-powder.com/tungsten-oxide.html Spraying method provides a possibility to prepare a WO3 electrochromic film with large-area high cycle stability by a low-cost solution method. However, the current research mainly produces…