Similar to tungsten-copper alloy powder and tungsten nickel iron alloy powder, tungsten-silver (W-Ag) alloy powder can also be used to manufacture tungsten cubes popular among cryptocurrency enthusiasts. In terms of physical and chemical properties, the raw materials used for tungsten cubes are all tungsten-based alloy powders, thus exhibiting characteristics of metallic tungsten, such as high density, high melting point, and good wear resistance. However, due to the different binders used in tungsten-copper, tungsten nickel iron, and tungsten-silver alloy powders, the physical and chemical properties of the prepared cubes still vary.

Specifically, tungsten-silver alloy cubes are silver-white in color with a metallic luster, with a density of 11.75–16.1 g/cm3, hardness of 75–180 HB, and bending strength of 75–726 MPa. Compared to tungsten-copper alloys, they have relatively lower strength and hardness but better electrical and thermal conductivity, plasticity, and oxidation resistance. Note: The density, hardness, and bending strength of W-Ag alloys change with different raw material ratios.

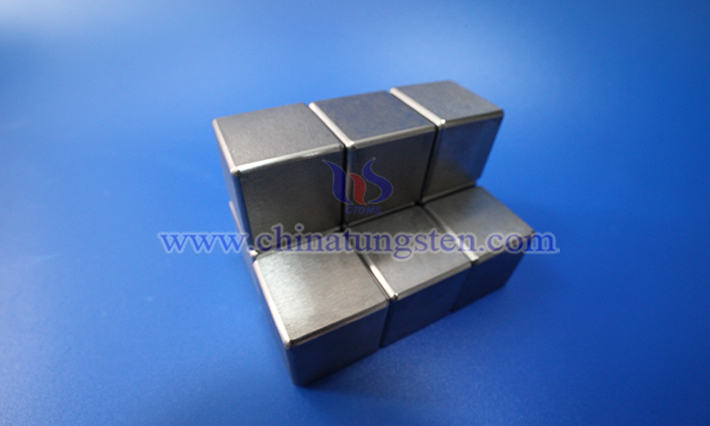

In terms of definition, a W-Ag alloy cube is a block composed of tungsten and silver, with the English name tungsten silver alloy cube. The silver content in commonly used cubes generally ranges from 30% to 80%, so it is also called silver-tungsten alloy.

In terms of production process, due to the significant difference in melting points between tungsten and silver, the alloy cannot be produced by melting and casting methods and is generally manufactured using powder metallurgy. Powder metallurgy refers to the technology of directly producing products from mixed tungsten and silver powders through pressing, forming, sintering, and other processes.

In terms of applications, tungsten-silver alloy cubes are suitable as counterweight blocks for sports equipment, high-temperature-resistant components, paperweights, and souvenirs.