Tungsten cubes can be produced not only from tungsten-copper (W-Cu) alloy powder but also from tungsten nickel iron (W-Ni-Fe) alloy powder. Although both W-Cu alloy powder and W-Ni-Fe alloy powder are types of high-density tungsten-based alloy powders, the production process parameters and physical-chemical properties of the resulting cubes differ due to the different binders. Since the basic information on W-Cu alloy cubes has already been introduced, the following presents the basic information on tungsten nickel iron alloy cubes.

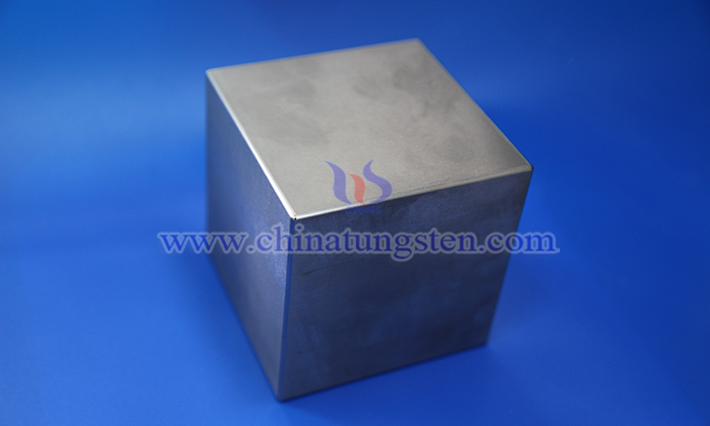

In terms of definition, a W-Ni-Fe alloy cube is a block composed of chemical elements such as tungsten, nickel, and iron, with the English name tungsten nickel iron alloy cube and a silver-white color. The tungsten content in commonly used alloys generally ranges from 90% to 98%, while the added nickel-to-iron ratio is typically 7:3 or 1:1.

In terms of physical and chemical properties, it combines the advantages of tungsten, nickel, and iron, primarily manifested in high melting point, high density (~18.8 g/cm3), high strength, good plasticity, excellent wear resistance, high thermal conductivity, low thermal expansion coefficient, strong radiation resistance, and certain ferromagnetism. It is worth noting that the cube's wear resistance, high melting point, and high density are mainly contributed by tungsten metal, while nickel and iron primarily contribute plasticity and toughness.

In terms of production process, it can be manufactured using traditional powder metallurgy (P/M) or injection molding technology (PIM). The P/M process flow is: mixing (tungsten powder, nickel powder, and iron powder) → mixing → pressing → pre-sintering → liquid-phase sintering → heat treatment → blank cutting → aging → final cutting → finished product. The PIM process flow is: mixing feedstock (tungsten powder, nickel powder, iron powder, and binder) → granulation → injection → debinding and pre-sintering → sintering → heat treatment → finished product.

In terms of applications, tungsten nickel iron alloy cubes can be used as industrial counterweights, balance blocks for consumer electronic products, and paperweights.