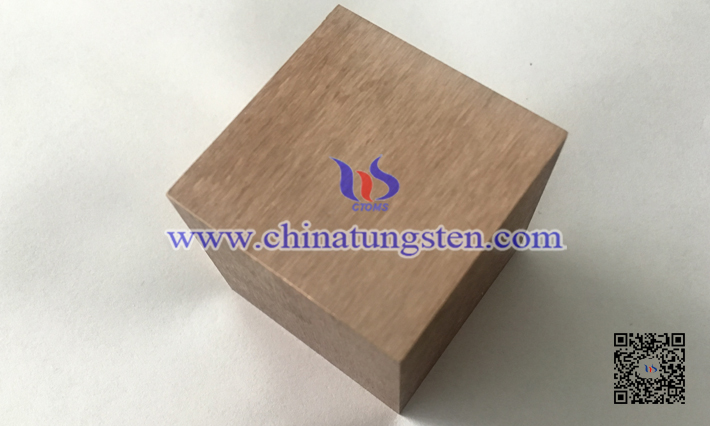

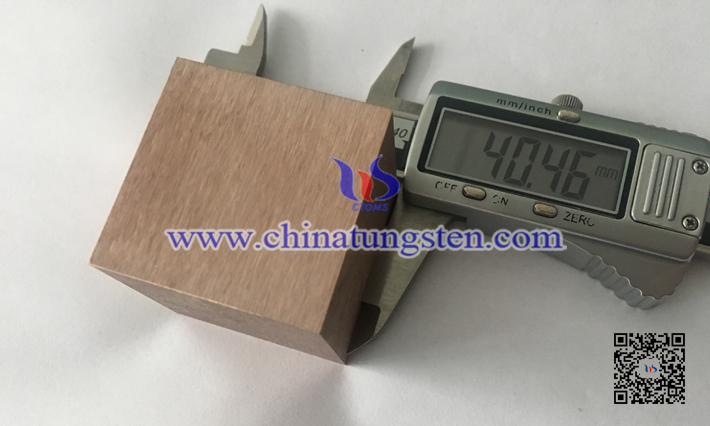

Depending on the application field, the physical and chemical properties of tungsten-copper (W-Cu) alloys, such as shape, raw material ratio, color, and density, vary. Shapes can include cubes, rectangular prisms, cylinders, spheres, tubes, and fine wires. However, under the same raw material ratio and production process conditions, W-Cu alloys of different shapes exhibit similar physical and chemical properties. The following introduces the basic information on tungsten-copper alloy cubes.

In terms of definition, a tungsten-copper alloy cube is a two-phase pseudo-alloy composed of refractory metal tungsten as the hard phase and copper as the binder phase, with the English name tungsten copper alloy cube. The copper content in commonly used alloys generally ranges from 7% to 50%.

In terms of physical and chemical properties, it combines the advantages of tungsten and copper, such as high melting point, high density, high strength, high hardness, low thermal expansion coefficient, high-temperature resistance, wear resistance, oxidation resistance, and good electrical and thermal conductivity. However, it should be noted that due to differences in raw material ratios, the physical indicators of the alloy also vary: for the WCu7 grade alloy, the density is 17.5 g/cm3, thermal conductivity is 150 W/(m·K), and thermal expansion coefficient is 5.5 1/K; for the WCu30 grade alloy, the density is 14.1 g/cm3, thermal conductivity is 220 W/(m·K), and thermal expansion coefficient is 8.8 1/K. Overall, within a certain range of raw material ratios, as the copper content increases, the alloy's color leans more toward copper's hue, while the density decreases, and both thermal conductivity and thermal expansion coefficient increase; the opposite is also true.

In terms of production process, due to the significant difference in melting points between tungsten and copper, W-Cu alloy cubes cannot be produced by melting and casting methods and are generally manufactured using powder metallurgy technology. The steps of powder metallurgy technology include preparing tungsten powder and copper powder, mixing ingredients, press forming, sintering infiltration, and cold processing. However, with the continuous advancement of science and technology, alloy cubes can also be produced using 3D printing technology.

In terms of applications, tungsten-copper alloy cubes can be used as paperweights, souvenirs, fishing weights, sports equipment counterweights, and mobile phone vibrators.