As a typical representative of tungsten-based alloys, tungsten nickel copper alloy is widely used in aerospace, aviation, mechanical equipment, and other fields due to its excellent thermal, mechanical, electrical, and chemical properties. The following introduces the basic information of this alloy.

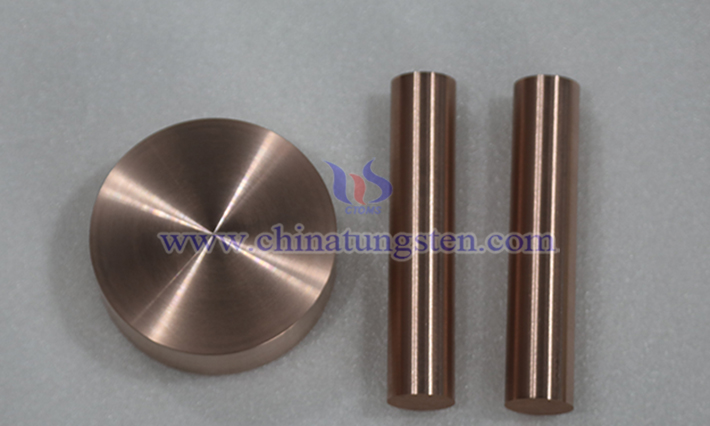

In terms of definition, tungsten nickel copper alloy is an alloy with tungsten as the matrix and a small amount of nickel, copper, and other chemical elements added, with the English name tungsten nickel copper alloy. The nickel-to-copper ratio in commonly used alloys is generally 3:2.

In terms of physical and chemical properties, it features non-magnetic, non-radioactive, environmentally friendly, high density (16.5–18.75 g/cm3), high tensile strength (700–1000 MPa), high thermal conductivity (5 times that of die steel), low thermal expansion coefficient (only 1/2–1/3 that of iron or steel), strong radiation shielding capability, good electrical conductivity, weldability, and processability.

In terms of production process, the production steps include: first uniformly mixing tungsten oxide, nickel oxide, and copper oxide powders, then reducing the mixed raw materials to obtain Tungsten Nickel Copper mixed powder, pressing into blanks, and finally sintering and cooling to room temperature to obtain the desired product.

In terms of applications, it can be used as: Shielding material, with good absorption effects on X-rays and gamma rays, suitable for radiation shielding fields sensitive to magnetic environments; Electrical contacts for high-voltage electrical switches and electrodes for electrical processing, mainly due to the alloy's strong electrical conductivity and high-temperature resistance; Gyroscope rotors and components for equipment operating in magnetic fields, owing to its good anti-magnetic performance; Various counterweights.