Like cerium-tungsten, lanthanum-tungsten, zirconium-tungsten, and yttrium-tungsten electrodes, the thorium-tungsten electrode is a product made by doping metal tungsten with the corresponding oxide. Though it was the earliest used and remains the best-performing tungsten electrode for welding to date, its strong radioactivity has led to its gradual replacement by rare earth tungsten electrodes. Below is an introduction to the basic information about thorium-tungsten electrodes.

1. Definition

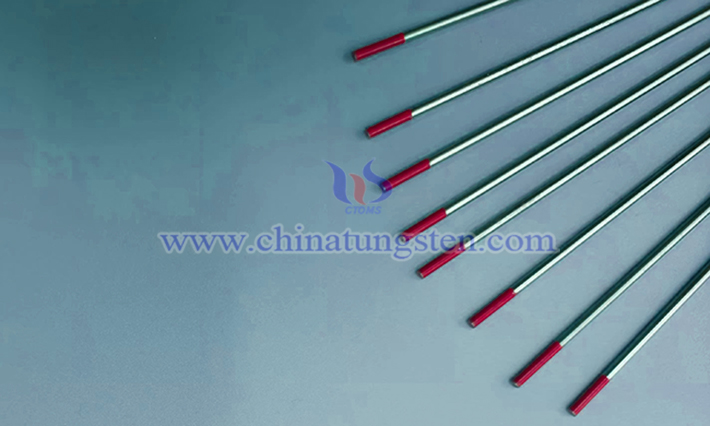

Known as Thoriated Tungsten Electrode in English, it is a tungsten electrode containing 1-1.2% thorium oxide (ThO?), marked with color codes of yellow, red, purple, or orange-yellow. Its diameter ranges from 1.0 to 12.0 mm, with lengths typically of 150 mm or 175 mm.

2. Performance

It features a low electron work function, high recrystallization temperature, strong current-carrying capacity, good electrical conductivity, mechanical cutting properties, and weldability. As a result, under normal conditions, it has a longer service life than pure tungsten electrodes, with a more stable arc beam compared to pure tungsten or zirconium-tungsten electrodes, and it initiates arcs more easily.

Radioactivity is another characteristic of thorium-tungsten electrodes. During production and use, the product exhibits varying degrees of radioactive contamination. Radiation affects the human body in two forms: external irradiation and internal irradiation through inhalation or ingestion via the respiratory and digestive systems. Note: Due to this radioactive drawback, production of this electrode type has been restricted in Europe and the United States, with lanthanum-tungsten electrodes currently considered the most suitable replacement for thorium-tungsten electrodes.

3. Production Process

The process begins by doping tungsten powder and thorium oxide powder in a 49:1 mass ratio, followed by pressing and sintering to produce semi-finished thorium-tungsten rods. These rods are then processed through rotary forging (annealing), wire drawing, straightening, cutting, and polishing to manufacture the finished thorium-tungsten electrodes.

4. Applications

Primarily used in direct current welding fields, serving as a negative electrode for direct current or as a positive electrode material for carbon steel, stainless steel, nickel alloys, titanium alloys, etc.

A key material in processes such as argon arc welding and plasma welding, applied in fields like new energy manufacturing, shipbuilding, vehicle manufacturing, engineering machinery, hardware processing, and nuclear and aerospace manufacturing.