As a type of hard alloy, steel-bonded hard alloy combines the excellent properties of hard compounds and steel, primarily used in the manufacturing of wear-resistant parts and machine components. Below is an introduction to the basic information about this alloy material.

1. Definition

It is an alloy material with refractory metal hard compounds as the hard phase and steel as the binder phase. Generally, the proportion of hard compounds ranges from 30% to 50%, with the remainder consisting of a steel matrix. Common hard compounds include tungsten carbide, titanium carbide, and titanium nitride.

2. Performance

It possesses the excellent characteristics of ordinary hard alloys, such as high melting point, high strength, high hardness, high elastic modulus, wear resistance, corrosion resistance, high-temperature resistance, and oxidation resistance, as well as the good properties of steel, including machinability, heat treatability, forgeability, weldability, and toughness.

Note: The primary role of the hard phase is to enhance the product’s room-temperature hardness, high-temperature hardness, and wear resistance; the binder phase not only binds the hard phase but also allows the alloy to achieve specific physicochemical properties by adjusting its composition.

3. Production Process

Powder Metallurgy Method: This involves preparing raw material powders, shaping the powders into green compacts of the desired form, sintering the compacts, and performing post-processing on the products. Advantages include material savings, reduced production costs, high product purity, and suitability for producing large quantities of identical shapes; a disadvantage is the need to consider part size when not producing in bulk.

Hot Isostatic Pressing (HIP): This method involves placing the product in a sealed container, applying uniform pressure from all directions while simultaneously applying high temperature to sinter and densify the product.

In addition, steel-bonded hard alloys can also be produced using infiltration methods and hot pressing techniques.

4. Applications

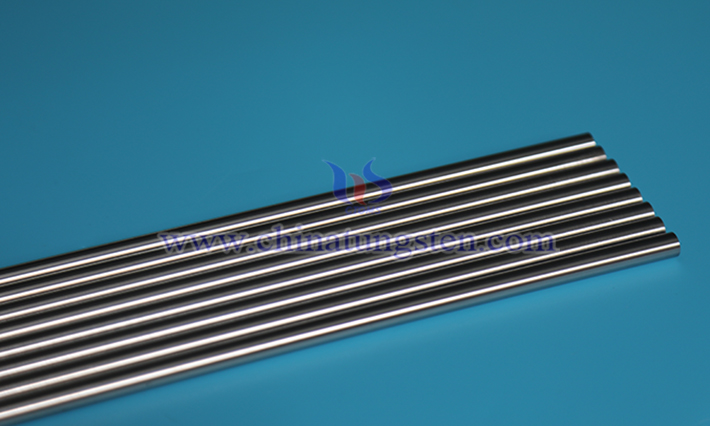

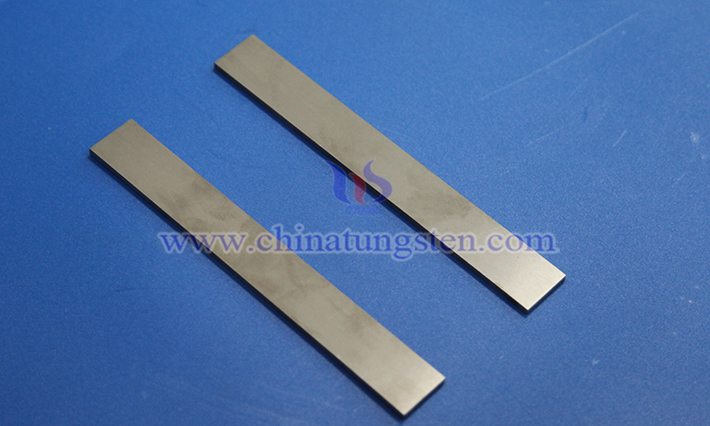

Used in the manufacture of cutting tools, rock drilling tools, mining tools, drilling tools, measuring instruments, wear-resistant parts, metal grinding tools, cylinder liners, precision bearings, rocket nozzles, and hardware molds.