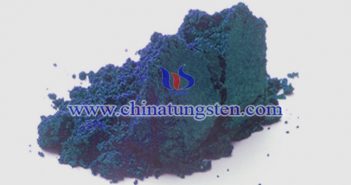

Blue tungsten oxide powder, also known as WO2.92, is a new type of infrared absorption material. Certainly, blue tungsten oxide may also be added to the sintered tungsten skeleton to increase the density of the skeleton. When the skeleton of blue tungsten oxide is reduced and sintered under a hydrogen atmosphere, the blue tungsten oxide is reduced to fine grain size tungsten powder. In order to study the effect of adding blue tungsten oxide into sintered tungsten skeleton on copper…