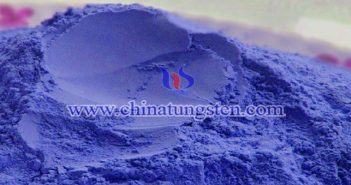

Nano grain size blue tungsten oxide is a new type of nanomaterial that may be applied for producing heat-insulating glass window film. As you may have known, what we usually call blue tungsten oxide powder refers to agglomerates on the metallurgical definition. The agglomerates are the basic composition of the powder. Therefore, the study of the microstructure needs to start with the formation of the agglomerates. Firstly, the surface morphology of the powder, that is, the appearance of the agglomerate,…