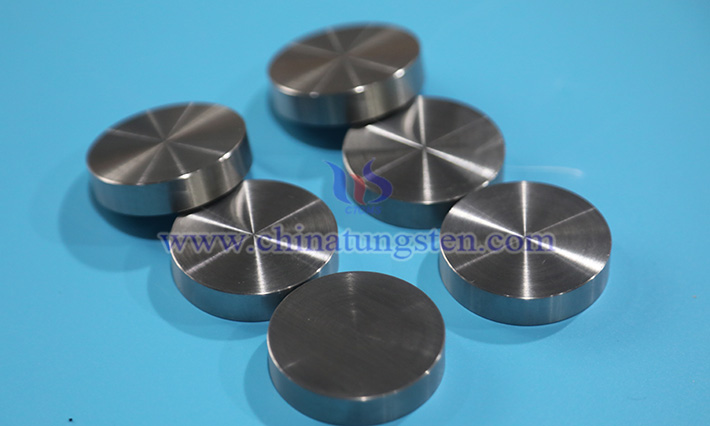

Compared to copper, aluminum, titanium, and molybdenum targets, tungsten targets exhibit significant advantages in high-temperature resistance, high density, chemical stability, mechanical strength, and thin film quality. Their stable performance in high-temperature, high-corrosion, and high-precision sputtering processes makes them the preferred material in semiconductors, medical devices, new energy, and optical coating fields.

1.Comparison with Copper Targets

Copper targets, due to their excellent electrical conductivity and lower cost, are widely used for depositing interconnect layers in semiconductors. However, copper’s low melting point makes it prone to thermal degradation during high-power sputtering, affecting thin film quality. In contrast, tungsten targets’ high-temperature resistance and chemical stability make them more suitable for high-intensity, long-duration sputtering processes. Additionally, copper targets are susceptible to oxidation in complex chemical environments, whereas tungsten targets’ superior chemical stability significantly reduces such issues.

2.Comparison with Aluminum Targets

Aluminum targets, valued for their lightweight nature and low cost, are commonly used in optical and decorative coatings. However, aluminum’s low melting point and poor corrosion resistance limit its application in high-temperature or chemically active environments. Tungsten targets’ high density and high-temperature resistance give them an edge in scenarios requiring high precision and durability, such as semiconductor barrier layers or thin film deposition for new energy batteries. Moreover, aluminum targets have lower mechanical strength, making them prone to deformation during high-energy sputtering, while tungsten targets’ excellent mechanical properties ensure stable sputtering performance.

3.Comparison with Titanium Targets

Titanium targets, known for their good corrosion resistance and biocompatibility, are often used in coating preparation for medical and aerospace applications. However, titanium’s lower density and melting point compared to tungsten restrict its use in high-density thin films and high-temperature environments. Tungsten targets’ high density and thermal stability enable the formation of more uniform and dense thin films in semiconductors and optical coatings. Furthermore, tungsten alloy targets, through elemental adjustments, can enhance toughness, addressing the shortcomings of pure titanium targets in high-intensity sputtering.

4.Comparison with Molybdenum Targets

Molybdenum targets, like tungsten targets, are refractory metal targets with high melting points and chemical stability. However, molybdenum’s lower density results in slightly inferior sputtering efficiency and thin film uniformity compared to tungsten targets. Additionally, molybdenum targets are less stable than tungsten in certain high-corrosion environments (e.g., fluorine-containing gases). Tungsten targets’ high density and excellent thermal conductivity provide advantages in high-power sputtering and complex chemical environments, making them suitable for manufacturing fuel cells and solar cells in the new energy sector.