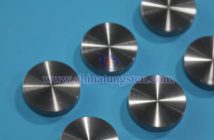

cemented Carbide balls (also known as tungsten carbide balls) are widely used in precision bearings, sealing valves, oil drilling, mining tools, and other fields due to their high hardness, wear resistance, corrosion resistance, and high temperature resistance. Surface treatment is one of the key technologies for improving the performance of cemented carbide balls.

I. Purposes of Surface Treatment Technology

1. Improve wear resistance: Reduce wear in high-friction environments.

2. Enhance corrosion resistance: Extend service life in harsh chemical environments.

3. Improve surface finish: Increase accuracy and reduce the coefficient of friction, making it suitable for high-precision instruments.

4. Increase surface hardness: Further enhance surface properties.

5. Optimize lubricity: Reduce friction and wear, and extend service life.

II. Common Surface Treatment Technologies for Cemented Carbide Balls

1. Precision Grinding and Polishing

Process description: Through mechanical grinding and polishing, tiny surface defects are removed and the surface finish and smoothness are improved. Grinding usually uses diamond grinding wheels or grinding fluids, while polishing uses finer grinding media.

Advantages: Significantly improve surface quality, reduce friction coefficient, and are suitable for high-precision applications (such as precision bearings).

Applications: Commonly used for the final processing of cemented carbide balls to ensure dimensional accuracy requirements.

Process flow: Wet grinding → Drying → Screening → Polishing → Inspection.

2. Surface Coating Technology

(1) Physical vapor deposition (PVD)

Through vacuum environment deposition of thin films (such as TiN, TiC, DLC (diamond-like carbon coating)), the surface hardness and wear resistance are improved.

Advantages: The coating has high hardness, low friction coefficient, and strong corrosion resistance.

Applications: Suitable for oil drilling tools and cemented carbide balls in high-temperature environments. (2) Chemical Vapor Deposition (CVD) Deposit carbide or nitride coatings at high temperatures to enhance surface properties. Advantages: Strong coating adhesion, suitable for extreme working conditions. Limitations: High temperature processes may affect substrate properties. (3) Plasma Spraying Spray ceramic or metal coatings to improve wear resistance and corrosion resistance. Applications: Cemented carbide ball teeth for mining and tunneling.

3. Surface Carburizing/Nitriding Process Description: Carbon or nitrogen atoms are infiltrated into the surface of the cemented carbide ball through high temperature treatment to form a high-hardness compound layer (such as WC or TiN). Advantages: Significantly improve surface hardness and wear resistance. Limitations: The carbon content needs to be precisely controlled to avoid excessive carbon content leading to increased brittleness. Applications: Suitable for occasions requiring high wear resistance, such as coal mining machine drilling tools.

4. Laser Surface Treatment

Process Description: A laser beam is used to modify the surface of a cemented carbide ball, such as through laser cladding or laser quenching, to create a high-hardness, wear-resistant surface layer.

Advantages: High processing precision, localized modification capabilities, and a minimal heat-affected zone.

Applications: Suitable for high-end cemented carbide balls, such as those used in aerospace or precision instruments.

5. Chemical Treatment (such as Acid or Alkaline Cleaning)

Process Description: Chemical solutions are used to remove surface oxides or impurities, improving surface cleanliness and preparing for subsequent coating or use.

Advantages: Simple operation and low cost.

Limitations: Suitable only for surface cleaning; it does not directly enhance hardness or wear resistance.

6. Ion Implantation

Process Description: Specific ions (such as nitrogen and carbon) are implanted into the surface of a cemented carbide ball to alter its surface chemical composition and structure.

Advantages: Precise control of surface properties, enhancing hardness and corrosion resistance.

Applications: Suitable for applications requiring high precision and high wear resistance, such as instrumentation.