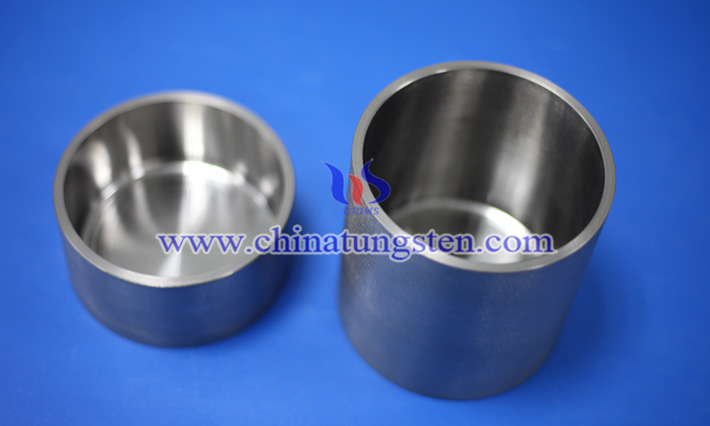

Tungsten crucibles operating in high-temperature environments must have good thermal stability and thermomechanical compatibility, especially when used with other structural materials (such as graphite, ceramic, quartz glass), and its coefficient of thermal expansion (CTE) becomes a key factor in the design and use process.

The coefficient of thermal expansion of tungsten in the range of room temperature to 2500°C is roughly between 4.5 × 10??/K and 5.5 × 10??/K, which is much lower than that of general metals such as steel (about 12 × 10??/K) or aluminum (about 23 × 10??/K), but slightly higher than that of ceramic materials. This low thermal expansion means that tungsten exhibits less dimensional variation during heating and cooling, helping to maintain its geometric stability and sealing properties, making it particularly suitable for use as a high-precision, high-temperature container material.

However, W crucibles are not used in isolation and are often combined with other materials to form composite structures or contact interfaces with melting equipment. If the thermal expansion coefficient of the interface material is too different, thermal stress may occur during frequent thermal cycles, resulting in cracking, deformation and even failure of the material. Therefore, when designing crucibles, it is necessary to fully consider their thermal expansion characteristics and adopt a reasonable structure and material matching strategy.

1. Design optimization strategy:

Thickness and shape optimization

Reducing the wall thickness of the crucible can reduce the overall thermal stress accumulation, but it does not affect its structural strength. Uniform wall thickness, thickening the bottom, and rounded edges are often used in the design to avoid stress concentration and enhance the crucible's crack resistance during thermal cycling.

Interface transition material design

The introduction of a transition layer between the crucible and a material with a large difference in thermal expansion coefficient, such as an intermediate ceramic or carbon-based cushion, can alleviate the stress mismatch caused by thermal expansion and contraction and improve the overall reliability of the system.

Multi-stage temperature control design

The implementation of multi-zone temperature control in melting equipment or heat treatment system can effectively reduce the thermal gradient caused by temperature differences, which can effectively reduce deformation or rupture caused by thermal expansion differences.

Sintering process control

The thermal expansion properties of a crucible are also affected by its density, grain size and orientation. By optimizing the powder metallurgy sintering process, the grain is uniform and the porosity is minimized, which improves its thermal expansion stability and structural integrity.

Thermal stress simulation

The application of finite element analysis (FEA) tools to simulate and predict the thermal expansion behavior of crucibles in high temperature environments can provide designers with a quantitative basis, identify potential failure areas in advance, and guide dimensional and structural optimization.

2. Considerations in typical applications

In monocrystalline silicon or sapphire crystal pulling furnaces, the tungsten crucible needs to work in tandem with the quartz or sapphire interface. If the thermal expansion of the crucible is not properly controlled, it can cause the crystals to crack during the cooling phase or the clamping system to fail. Therefore, it is common to use thermal cushioning materials in combination with thermal cushioning materials in these scenarios, or to adjust the ramp rate to control thermal expansion stresses.