Superalloy is a kind of alloy material that can maintain excellent mechanical properties and corrosion resistance in a high-temperature environment, and is widely used in aerospace, gas turbine, nuclear energy equipment and other fields. Due to the generally high melting point of superalloys, some even exceeding 1500 °C, the preparation process puts forward extremely strict requirements for the high temperature resistance, chemical stability and structural strength of the container material.

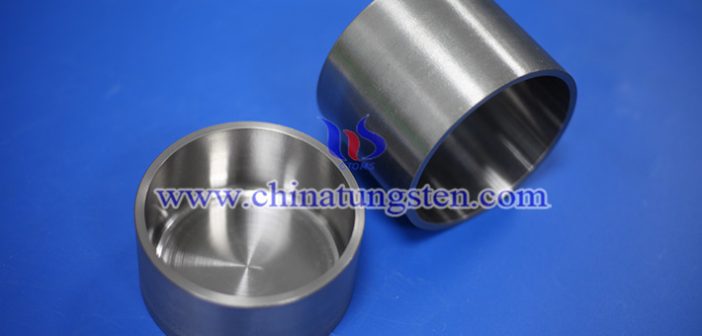

Tungsten crucible, as one of the most commonly used ultra-high temperature metal containers on the market, plays a key role in the smelting, casting and crystal growth of superalloys due to its excellent physical and chemical properties.

Tungsten has an extremely high melting point (about 3410°C), good thermal conductivity and low coefficient of thermal expansion, which makes the crucible able to withstand the thermal shock and high-temperature corrosion of high-temperature melts when dealing with nickel-based, cobalt-based, molybdenum-based and other superalloys. The chemical stability of tungsten also makes it non-reactive with most metal melts in a vacuum or inert atmosphere, thus avoiding the risk of alloy contamination and ensuring the purity of the superalloy composition and the uniformity of the structure.

In practical applications, W crucibles are often used in high-temperature processes such as electron beam melting, plasma melting and induction melting. For example, in the process of vacuum induction melting (VIM), the crucible can effectively reduce the interface reaction between the melt and the crucible material, and improve the consistency of the melted product. In the preparation of single crystal superalloy crystal pulling, the crucible provides a stable temperature control environment, which is conducive to the direction control and nucleation control of crystal growth.

However, W crucibles also have the disadvantage of being susceptible to oxidation. Therefore, in practice, it is often necessary to use it in a high vacuum or high purity inert atmosphere, combined with a cooling system or surface protection coating technology, to extend its service life.

In general, as a key carrier in the preparation process of superalloys, the performance of tungsten crucible directly affects the quality of alloy products and the repeatability of the process. With the continuous expansion of superalloy types and increasingly stringent process conditions, higher requirements are put forward for the design, purity and structure optimization of crucibles, and its position in the field of high-end metallurgy will continue to improve.