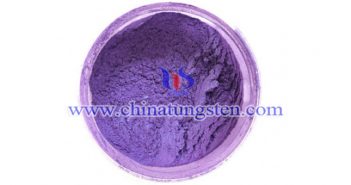

Nano violet tungsten oxide applying in thermal insulating glass is prepared by a light reduction method in an industrial rotary furnace (the raw material is APT). In order to realize the continuous industrial production of violet tungsten oxide with fine and uniform particle, and stable quality, scholars, after long-term production test and research, have found that the production of nano grain size violet tungsten oxide by rotary kiln should meet the following conditions: 1. The furnace tube has a certain…