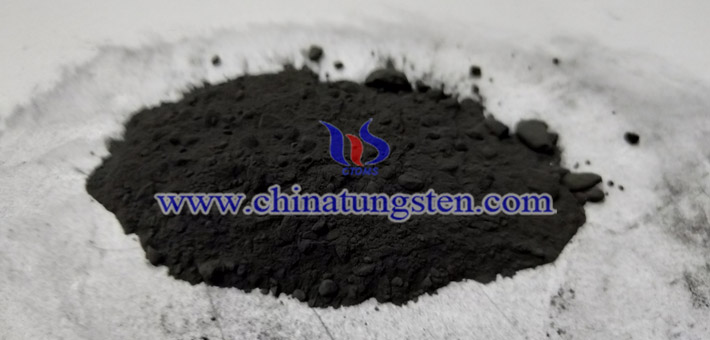

The researchers prepared ultrafine tungsten powder by the chlorination process. The obtained W powder has the characteristics of high purity, fine particles, uniform particle size distribution, spherical particles, and high thermal stability. Moreover, the ultrafine alloy made of tungsten chloride powder has good physical and mechanical properties, and is an ideal material for finishing, especially for watch processing.

More details, please visit:

http://tungsten-hexachloride.com/index.html

Preparation of Prepare Ultrafine Tungsten Powder by Chlorination Process

The chlorination is carried out in quartz equipment. At a certain temperature, the crude tungsten powder is passed through chlorine gas to generate tungsten hexachloride (WCl6) gas and then enters the reduction furnace. Ultrafine tungsten powder is prepared by the gas phase reduction with hydrogen. And tungsten powder is loaded into the collector with argon gas. Wherein, the chlorination temperature is 650-700 °C. The reduction temperature is 1000-1050 °C. The gas flow of the equipment Cl2 is 6-7L/min, Ar is 1-1.5L/min, H2 is 13-14L/min. The chlorination rate increases with the increase of chlorination temperature.