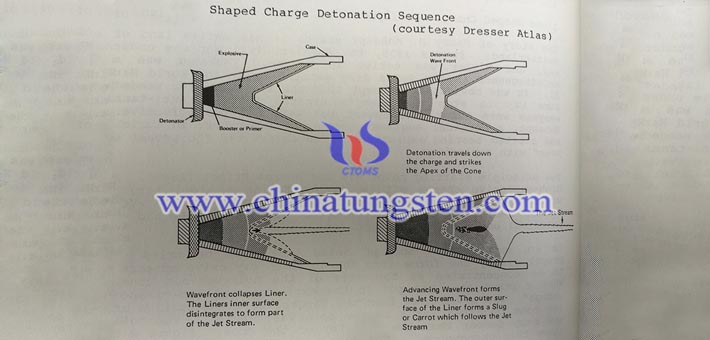

How to make shaped charge obtain a more ideal armor piercing effect? It is a good idea to choose tungsten alloy as the material of shaped charge liner material. The armor piercing ability of shaped charge is proportional to the square of the density of shaped charge liner material. Therefore, the use of high density tungsten alloy shaped charge liner can make the shaped charge achieve better armor-piercing effect.

More details, please visit:

http://www.tungsten-alloy.com/en/alloy04.htm

According to the experts, tungsten alloy (W-Ni-Fe alloy and W-Ni-Cu alloy) contains 80%-98% tungsten along with small amounts of nickel, iron and copper elements. Wherein, W-Ni-Fe alloy has comparatively higher strength and ductility than W-Ni-Cu alloy. After going through compacting and sintering process, tungsten is alloyed with other metals, all beginning as a form of powder. High density tungsten alloy is sintered by powder metallurgy for 60-90min at working temperatures ranging from 1500 to 1525 °C. The sintering temperatures and atmospheres are critical factors for attaining certain expected engineering properties, such as high tensile strength and elongation.