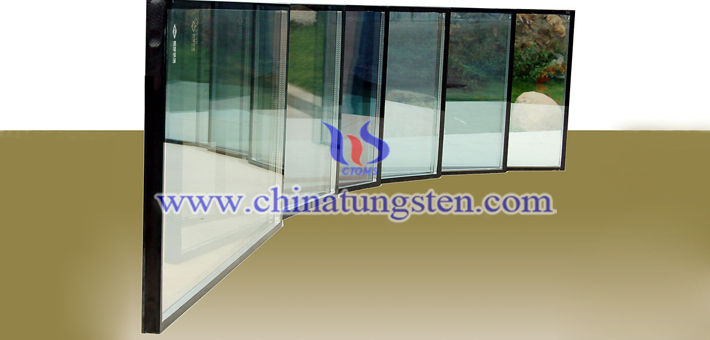

Cs doped tungsten oxide may be used to prepare infrared ultraviolet shielding material, which is more and more widely applied to heat insulating building glass. Wherein, the Cs doped tungsten oxide powder used is Cs doped tungsten oxide nano powder, and the Cs doped tungsten oxide nanopowder can be prepared by the following steps:

Prepare a certain concentration of sodium tungstate solution by using sodium tungstate as raw material. And the tungstic acid sol is obtained by cation resin exchange. Then, an appropriate amount of citric acid solution, ethanol and a certain concentration of cesium carbonate solution are added in tungstic acid sol, uniformly stirred, to obtain a precursor liquid of hydrothermal reaction. And the precursor liquid with citric acid concentration of 0.36moL/L and ethanol volume percentage of 56% and citric acid concentration of 0.55moL/L is prepared separately. And then the precursor liquid is placed in the autoclave, reacted at 190°C for 1-5 days. And the obtained precipitate is subjected to ultrasonic water washing, alcohol washing, centrifugation and drying treatment to obtain Cs doped tungsten oxide powder.

More details, please visit:

http://www.tungsten-powder.com/cesium-tungsten-bronze-chinatungsten.html

According to the diffuse reflectance absorption spectrum of CsxWO3 powder synthesized in 56% ethanol-containing precursor liquid, the absorbance of CsxWO3 in the visible region and short-wave near-infrared region is gradually enhanced with the extension of reaction time. In addition, the CsxWO3 synthesized in the ethanol-containing precursor liquid has a lower absorbance in the short-wave near-infrared region than the CsxWO3 synthesized in the ethanol-free precursor liquid. This may be due to the fact that although ethanol is added to the precursor liquid, and the growth of the crystal is promoted, the simultaneous presence of citric acid and ethanol may cause dehydration reaction of the two to form triethyl citrate, which reduces the reducing atmosphere in the system and affects the reduction reaction continues, so that the cesium ions enter the tungsten bronze structure and the free carrier concentration is low.