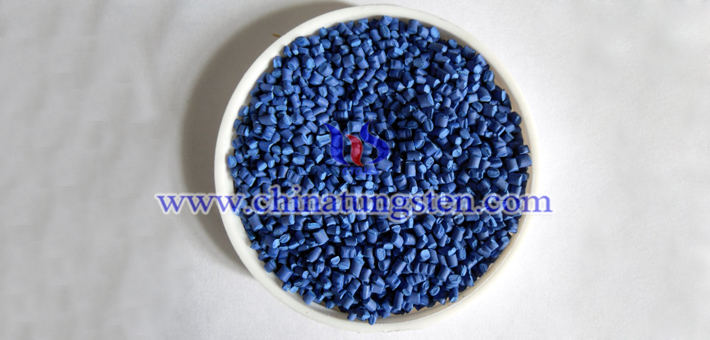

Experts have proposed a preparation method of cesium doped tungsten oxide nanopowder for ceramic microsphere. The specific steps are as follows:

More details, please visit:

http://www.tungsten-powder.com/cesium-tungsten-bronze-chinatungsten.html

1.0 The raw material sodium tungstate and cesium nitrate are respectively dissolved in deionized water, and the tungsten salt solution is configured into tungstic acid solution through the exchange resin;

2.0 The tungstic acid solution, cesium salt solution and polyethylene glycol are mixed and continuously stirred under a water bath condition of 50-80°C for 1-3h to obtain hydrothermal reaction precursor liquid; the mass of polyethylene glycol is 1.5-3.0 times the mass of tungsten salt and cesium salt.

3.0 The precursor liquid is placed in a closed hydrothermal reaction kettle with a stirring device, and reacted at 180-300°C for 5-20h;

4.0 The hydrothermal reaction precipitate is repeatedly washed with deionized water, dried at 80-120°C for 8-12h, and pulverized by a jet mill, and then calcined. The air pressure in the crushing chamber is controlled at 0.5-1.0MPa, and the pulverization speed is set to 2000-5000rpm. The calcination process is carried out in a vacuum atmosphere, the temperature is raised to 300-800°C at a rate of 2-10°C/min, and the heat treatment is continued for 1-2h to obtain cesium doped tungsten oxide nano powder.