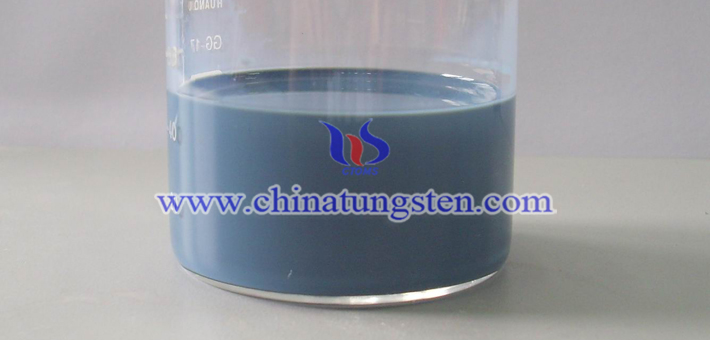

CsxWO3 may be used to produce thermal insulation dispersion. And the CsxWO3 powder used is nano grain size CsxWO3 powder, and naturally, the prepared dispersion is also nano dispersion. The obtained dispersion is actually an aqueous dispersion, that is, slurry of CsxWO3 nanopowder, similar to the presence of liquid.

As you may have known, when dispersing or grinding the slurry of nanopowder, if appropriate surface modifier is not added, and the mechanical strength of grinder alone is used for dispersion grinding, generally, the nanopowder can only be dispersed and ground to the grain size of 300-800nm. And the particle size can no longer be reduced. This is because when the particle size is less than 300nm, the specific surface area of the powder rises rapidly, and the van der Waals force effect is intensified. At this time, the powder is in a state of being extremely unstable and easily re-agglomerated, and even if the aggregated powder is broken by the grinding ball, it is easy to agglomerate again, unless the appropriate surface modifier is added to continue to reduce the particle size to the primary particle size. In other words, if CsxWO3 powder is processed in accordance with the above method, it is also necessary to add an appropriate surface modifier to reduce the particle size to primary particle size.

More details, please visit:

http://www.tungsten-powder.com/cesium-tungsten-bronze-chinatungsten.html