Based on differences in chemical composition and structural components, common hard alloys can be categorized into steel-bonded hard alloys, tungsten-cobalt alloys, tungsten-titanium-tantalum-cobalt alloys, and Tungsten-Titanium-cobalt alloys, with their physicochemical properties and applications being largely similar.

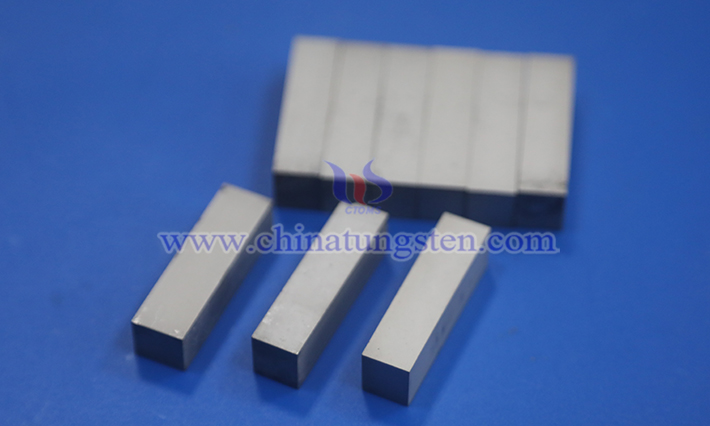

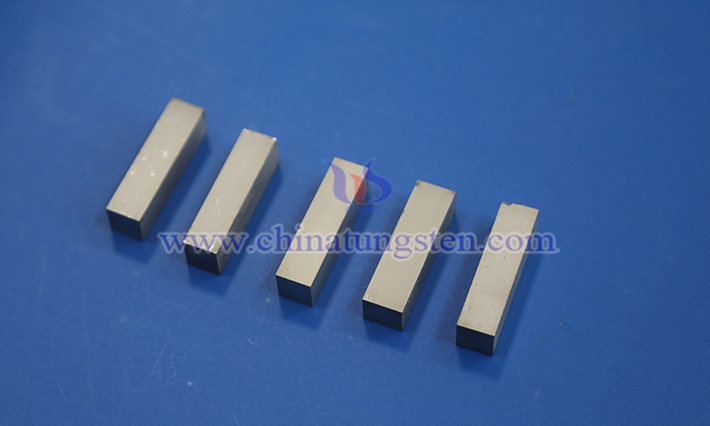

Tungsten-titanium-cobalt hard alloys, also known as YT-class hard alloys, are composed of tungsten carbide (WC), titanium carbide (TiC), and metallic cobalt (Co), with the English name cemented titanium tungsten carbide. Typically, the Co content in the alloy ranges from 4% to 10%, TiC from 5% to 30%, with the remainder being WC.

In terms of physicochemical properties, YT-class hard alloys combine the characteristics of WC, TiC, and Co, featuring a high melting point, high density, great hardness, excellent wear resistance, good red hardness, and strong oxidation resistance. Notably, compared to tungsten-cobalt hard alloys, YT-class alloys exhibit lower bending strength and thermal conductivity. The specific properties of YT-class alloys are closely related to raw material ratios and grain sizes: bending strength decreases as TiC content increases, while hardness improves with smaller carbide (WC and TiC) grain sizes.

Regarding production processes, the preparation of YT-class hard alloys involves compounding WC-TiC with WC powder and Co powder, followed by batching, ball milling, drying, adding forming agents, pressing, and sintering. The advantage of this production technique is that it can enhance bending strength without compromising wear resistance, thereby addressing issues like excessive wear and blade burning during use.

In terms of applications, Tungsten-Titanium-cobalt hard alloys are used to manufacture cutting tools, making them suitable for processing tough materials such as steel.