In the field of advanced materials, tungsten niobium alloy, a typical refractory metal composite, is gaining prominence as a critical foundational material in strategic sectors such as aerospace and high-end equipment manufacturing. This two-phase alloy system, composed of tungsten and niobium, achieves a complementary balance of tungsten’s high melting point and strength with niobium’s excellent ductility and corrosion resistance through elemental ratio control and microstructural design. Known as Tungsten Niobium Alloy or Niobium Tungsten Alloy, it demonstrates irreplaceable value in defense, military, and high-end civilian applications.

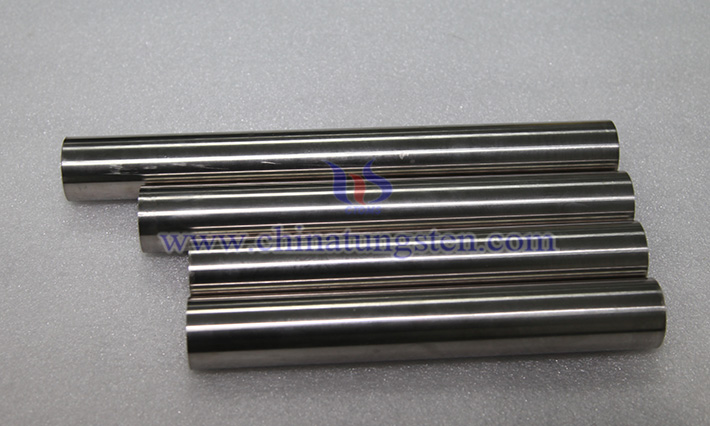

Image of tungsten niobium alloy

The properties of tungsten niobium alloy depend on the synergistic effects of its two-phase metals. Tungsten, one of nature’s highest-melting-point metals, imparts exceptional high-temperature strength and thermal shock resistance to the alloy, while niobium’s good ductility and resistance to liquid metal corrosion enhance the processability of tungsten-based materials. When tungsten content exceeds 60%, the microstructure features tungsten particles as the reinforcing phase, exhibiting wear and high-temperature resistance akin to pure tungsten. Conversely, when niobium dominates, the alloy displays cold-working plasticity and acid-alkali corrosion resistance similar to niobium.

Tungsten niobium alloy is produced through a combination of powder metallurgy and vacuum melting. The process includes: first, uniformly mixing niobium, tungsten, and alloying element powders in proportion, followed by pressing and sintering to form a pre-alloyed strip; then using vacuum electron beam melting or vacuum arc melting to purify and densify the strip into an ingot blank; and finally subjecting the ingot to cutting, extrusion, forging, rolling, and drawing for plastic forming to yield the final alloy product. This multi-process approach, integrating powder metallurgy, vacuum melting, and plastic processing, ensures uniform composition, dense microstructure, and optimized performance, meeting the material demands of aerospace and high-temperature electronic devices.

Image of tungsten niobium alloy

With its excellent high-temperature strength, good corrosion resistance, and superior processability, tungsten niobium alloy is widely used across critical fields. In aerospace, it is employed to manufacture high-temperature engine components that maintain stable mechanical properties under extreme heat. In the electronics industry, it serves as a cathode for electron tubes and a semiconductor sputtering target, meeting the needs of high-vacuum environments and precision machining. In medicine, its biocompatibility makes it suitable for orthopedic implants. Additionally, in the energy and chemical sectors, it is used to produce corrosion-resistant high-temperature pipes and reactor linings, enhancing equipment longevity.