Yellow tungsten oxide (WO?), produced by CTIA GROUP LTD, is a chemically distinctive compound. It appears as a fine yellow powder, insoluble in water yet soluble in alkaline solutions, with limited solubility in acids. Composed of one tungsten atom (W) bonded with three oxygen atoms (O), this atomic arrangement endows WO? with unique physical and chemical properties.

As an oxide of tungsten, yellow tungsten oxide holds a significant position within the family of tungsten compounds. It emerges from the interaction between tungsten and oxygen, a reaction that not only alters tungsten’s chemical form but also imparts a range of novel characteristics.

Additionally, yellow tungsten oxide is an N-type semiconductor material. Semiconductors are pivotal in modern technology due to their unique electrical properties—neither fully conductive like metals nor completely insulating like insulators, they exhibit controllable conductivity under specific conditions. As an N-type semiconductor, WO?’s internal electron movement and distribution underpin its potential value in electronics, enabling innovation in various electronic devices.

I. The Property Code of Yellow Tungsten Oxide

Yellow tungsten oxide manifests as a yellow or bright green fine crystalline powder, making it easily recognizable among compounds. Upon close inspection, its delicate texture and vibrant yellow or green hue highlight its distinctiveness. With a melting point of approximately 1473°C, its high thermal stability allows it to perform reliably in elevated temperature environments.

WO? exhibits strong oxidizing properties, playing a key role in numerous chemical reactions. In redox processes, it acts as an oxidant, oxidizing other substances while being reduced itself. For instance, in reactions with certain metals, WO? can strip electrons from metal atoms, converting them into metal ions, while potentially reducing itself to lower-valence tungsten oxides.

It also boasts excellent catalytic capabilities. In the petrochemical industry, WO? is frequently employed as a catalyst in reactions such as hydrocracking, dehydrogenation, and isomerization. In hydrocracking, it lowers the activation energy, enabling large hydrocarbon molecules to break down into smaller ones at relatively lower temperatures and pressures, enhancing the quality and yield of petroleum products. In dehydrogenation, it facilitates the removal of hydrogen atoms from organic compounds, forming unsaturated compounds critical for chemical production.

Moreover, yellow tungsten oxide exhibits decent electrical conductivity, making it suitable for electrolytic cells and electronic devices. In electronics, its conductivity supports the production of resistors, capacitors, and similar components. This property also enables its use in sensors, where it detects environmental changes—such as gas concentrations or temperature—and converts them into electrical signals for monitoring and control.

II. The Preparation Journey of Yellow Tungsten Oxide

Hydrothermal Method: This method utilizes a high-temperature, high-pressure aqueous environment to react tungstate with a reducing agent, yielding tungsten oxide. Initially, tungstate is dissolved in water to form a solution, where concentration and pH significantly influence the reaction. The solution is then transferred to a high-pressure reactor, combined with a reducing agent and water, and subjected to hydrothermal conditions. Parameters like temperature, pressure, and duration affect WO?’s morphology and purity. Post-reaction, WO? is separated via precipitation and filtration, with careful washing and drying to ensure purity and stability. This method offers controllable particle morphology, simple operation, mild conditions, and environmental friendliness, making it a promising green process.

Sol-Gel Method: This approach controls sol formation and gelation to produce uniformly dispersed WO? particles. Tungstate is dissolved in a solvent to form a sol, with solvent choice and sol concentration impacting gelation. Conditions such as temperature, concentration, and pH are adjusted to trigger gelation, forming WO? gel, where timing and temperature influence particle size and distribution. The gel is then dried and calcined to yield WO?, with drying and calcination temperatures affecting purity and performance. This method produces uniform, high-purity WO? suitable for high-performance applications, with the advantages of mild conditions and simplicity.

Microemulsion Method: A newer technique, this method uses a thermodynamically stable, transparent dispersion of surfactant, co-surfactant, oil, and water. Surfactant molecules form a monolayer at the oil-water interface, encapsulating oil or water droplets into nanoscale microreactors. For WO? preparation, a tungsten source and reactants are dissolved in the microemulsion’s aqueous phase. By controlling composition and conditions, reactions occur within these microreactors, forming WO? nanoparticles with restricted growth for precise size and shape control. The resulting nanoparticles are uniform, highly dispersible, and pure, offering broad prospects in nanomaterials.

III. Wide-Ranging Applications of Yellow Tungsten Oxide

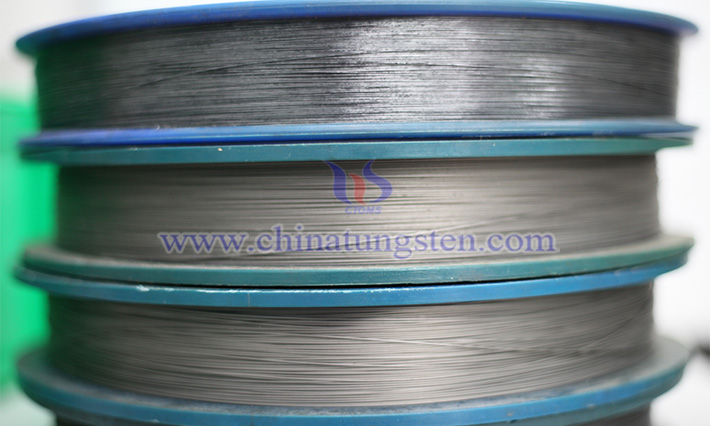

Electric Light Source Industry: WO? is a key raw material for tungsten filament production. In practice, it isn’t directly melted into filaments. Instead, hydrogen reduces WO? to tungsten powder at high temperatures. This powder is mixed with additives, shaped, and sintered into dense tungsten billets, which are then mechanically processed via swaging and drawing into fine filaments. In incandescent and halogen lamps, current heats the filament to incandescence, emitting bright light. Tungsten’s high melting point and conductivity ensure stability at high temperatures, enabling long-lasting, reliable lighting.

New Energy Sector: WO? is emergeng as a promising material, particularly in lithium-ion battery anodes. Its small particle size, large surface area, and high reactivity allow it to strongly adsorb lithium ions, enhancing battery energy density and extending electric vehicle range. Its good electron conductivity accelerates charge-discharge rates, reducing charging times and improving convenience. In smart car windows, nanoscale WO? enables electrochromic effects, adjusting tint based on light intensity to improve safety, privacy, and comfort while reflecting infrared radiation to reduce heat, enhancing energy efficiency and mileage.

Sensors: Nano-WO?’s gas sensitivity supports its use in automotive sensors, detecting harmful gases like carbon monoxide or nitrogen oxides to ensure air quality, and in exhaust monitoring to optimize emissions, reducing environmental impact.

Daily Life: WO?’s vivid yellow hue makes it a popular pigment for paints, coatings, and ceramics, adding vibrant, durable color to furniture, buildings, and artistic ceramics. As a fireproofing additive, it enhances materials’ heat resistance, slowing fire spread in buildings and improving safety in public spaces like malls and hotels.