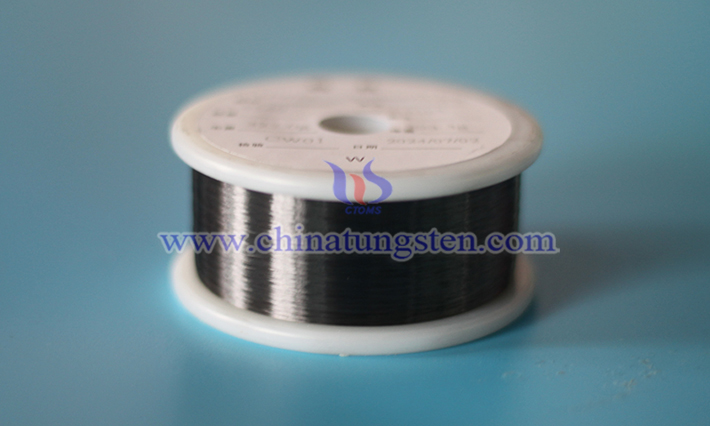

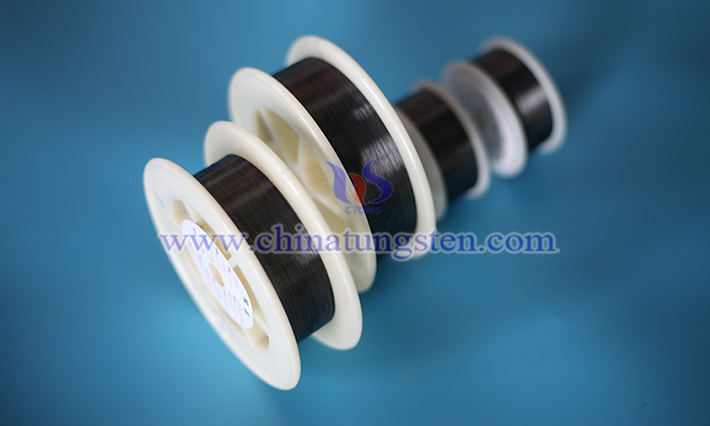

Cut-resistant tungsten wire is a specially treated or modified tungsten-based material with exceptional resistance to cutting, wear, and high temperatures, making it suitable for scenarios involving high mechanical stress or extreme environments. Its primary application areas include:

1. Photovoltaic Industry:

Silicon Wafer Cutting: Cut-resistant tungsten wire serves as a key material for the busbar in photovoltaic diamond wire, playing a crucial role in silicon wafer cutting. Its properties, such as wear resistance, high strength, and corrosion resistance, make the cutting process more efficient and precise, with a low breakage rate, helping to reduce production costs. As silicon wafers become thinner and diamond wires finer, the application prospects for cut-resistant tungsten wire continue to expand.

2. Textile Industry:

Cut-Resistant Gloves: Cut-resistant tungsten wire can be used to manufacture high-performance cut-resistant gloves. Compared to traditional materials, tungsten wire gloves maintain the same cut-resistance level while being thinner, softer, and significantly more comfortable and flexible to wear, making them ideal for various hand protection scenarios.

Other Cut-Resistant Textiles: While protective gear overlaps with the textile industry, the application of cut-resistant tungsten wire extends beyond gloves. It can also be used to produce cut-resistant fabrics and clothing, providing reliable protection in high-risk settings. These textiles offer high strength while retaining excellent softness and comfort.

3. Medical Industry:

Surgical Instruments: Due to its excellent flexibility and wear resistance, cut-resistant tungsten wire is widely used in surgical instruments. For instance, ultra-fine tungsten wire ropes can drive surgical robots or medical devices, enhancing the precision and success rate of surgeries. Additionally, tungsten wire can be used to create high-frequency electrosurgical knives, enabling low-power tissue cutting with reduced surgical smoke and thermal damage.

4. Other Industrial Applications:

High-Temperature Saw Wire: Cut-resistant tungsten wire can be used to produce high-temperature saw wires for cutting metals, ceramics, and other materials in high-temperature environments.

Bulletproof Fibers: When combined with other materials, cut-resistant tungsten wire can be used to create bulletproof fibers for manufacturing body armor, bulletproof helmets, and other protective gear.

Electronics and Vacuum Technology: Tungsten wire is commonly used in the production of electron tubes and electron guns, ensuring the stable operation of high-tech products. In vacuum technology, it serves as a hot cathode material in vacuum tubes and equipment.

Welding and Cutting Industry: In TIG welding and laser cutting, tungsten wire is used as an electrode material, capable of withstanding high temperatures and arc corrosion with ease.