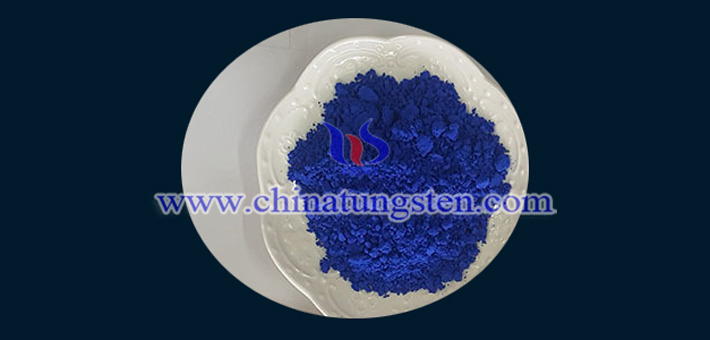

Cs0.33WO3 nanoparticles for heat insulating window glass are a new type of dingal particles. Also, it is an inorganic nanopowder. As you may have known, the preparation of nanopowders has always been a hot technology in the powder industry. Common nanopowder preparation methods include chemical methods and physical methods. Now, let's take a look at the chemical preparation methods of nanopowders.

More details, please visit:

http://cesium-tungsten-bronze.com/index.html

Some Chemical Reduction Methods for Producing Nanopowder

1.0 Vapor phase reduction method: a common method for preparing fine powder.

2.0 Carbothermal reduction method: The basic principle of the carbothermal reduction method is to use carbon black and SiO2 as raw materials, and carry out the carbothermal reduction reaction to obtain fine powder under the protection of nitrogen in a high temperature furnace. Different products can be obtained by controlling the process conditions.

3.0 Aqueous solution reduction method: using a reducing agent such as hydrazine hydrate, glucose or sodium borohydride to prepare an ultrafine metal powder or an amorphous alloy powder in an aqueous solution, and using a polymer to protect PVP to prevent agglomeration and reduce the grain size. The advantage is that the obtained particles have good dispersibility, the particle shape is substantially spherical, and the process can be controlled.